I-Cobalt Base Alloy enokumelana nokunxiba kunye nokudleka

Inkcazo

I-KF-3321 yi-cobalt-based alloy powder ene-accessory egqwesileyo yokunxiba kunye nokushisa okuphezulu kwe-oxidation.Ihlanganiswe ne-cobalt, i-chromium, i-tungsten, i-nickel, i-silicon, kunye ne-carbon, kwaye inokuthi iqulethe ixabiso elincinci le-aluminium, i-niobium, i-tantalum kunye nezinye izinto ze-alloy.

Iipropati zomgubo

Ubungakanani beNcam:I-KF-3321 inobungakanani besayizi ye-particle -140 ukuya kwi-325 mesh, eyenza ukuba ifaneleke kwizicelo ezahlukeneyo apho kufuneka ubungakanani be-particle.

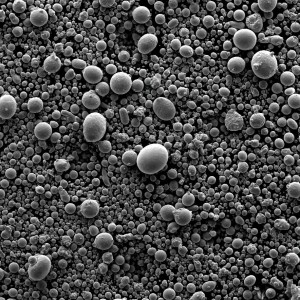

Uhlobo:I-KF-3321 yi-gas atomized powder, oku kuthetha ukuba iveliswa ngokunyibilikisa i-alloy kwaye emva koko i-atomizing ngegesi ephezulu yoxinzelelo.Oku kubangela ukumila komgubo ongqukuva, obonelela ngokuqukuqela kakuhle kunye nokuxinana kokupakisha.

Ukuqulunqwa:I-KF-3321 yi-cobalt-based alloy powder equlethe ipesenti ephezulu ye-cobalt, enika ukuxhathisa okugqwesileyo kokunxiba.Ukongezwa kwechromium kunye ne-tungsten kuphucula ngakumbi ukuxhathisa ukunxiba kunye nobushushu obuphezulu bokumelana ne-oxidation.I-Nickel, i-silicon, kunye nekhabhoni zinika amandla ongezelelweyo kunye nokumelana nokubola kwi-alloy.

Isicelo

I-KF-3321 yi-alloy powder eguquguqukayo enokusetyenziswa kumashishini ahlukeneyo kwizicelo ezifuna ukuxhathisa ukunxiba kunye nokushisa okuphezulu kwe-oxidation.Ezinye izicelo eziqhelekileyo ziquka:

Iivalvu zoxinzelelo lobushushu obuphezulu:I-KF-3321 ye-high-temperature oxidation resistance yenza ukuba ibe yinto efanelekileyo kwiivalvu zoxinzelelo lobushushu obuphezulu.

Amazinyo abone:Ukuxhatshazwa kwe-KF-3321 kunye nokuqina kwenza ukuba ilungele ukusetyenziswa kumazinyo e-saw, efuna izinto ezinzima ezinokumelana noxinzelelo kunye noxinzelelo lokusika.

Izikrufu zokukhupha:Ukumelana nokunxiba kwe-KF-3321 kunye nokushisa okuphezulu kwe-oxidation kwenza kube yinto efanelekileyo yokusetyenziswa kwizikrufu ze-extrusion, ezifuna izinto ezinokumelana nokushisa okuphezulu kunye noxinzelelo lwenkqubo ye-extrusion.

Iyafana neSt12:I-KF-3321 ineepropati ezifanayo kwi-St12, intsimbi ephantsi yekhabhoni esetyenziswa ngokuqhelekileyo kwishishini leemoto.Nangona kunjalo, i-KF-3321 inokumelana nokunxiba okungcono kakhulu kunye nokumelana nobushushu obuphezulu be-oxidation kune-St12, iyenza ibe lukhetho oluphezulu lwezicelo ezifuna ukuxhathisa ukunxiba kunye nokuzinza kobushushu obuphezulu.

Ngokubanzi, i-KF-3321 yi-powder ye-alloy ye-high-performance enika ukuxhathisa okugqwesileyo kunye nokushisa okuphezulu kwe-oxidation.Iimpawu zayo eziguquguqukayo zenza ukuba zilungele uluhlu olubanzi lwezicelo kumashishini ahlukeneyo.

Iimveliso ezifanayo

| Uphawu | Igama lemveliso | I-AMPERIT | I-METCO/AMDRY | WOKA | PRAXAIR | PAC |

| KF-331 | CoCrMoSi | 340 | 66/3002 | CO109 / 1247 | T400 | |

| KF-333 | CoCrMoSi | 342 | 68/3001/4800 | CO111 / 1248 | T800 | |

| KF-332 | CoCrWCNiSi | |||||

| KF-3321 | CoCrWCNiSi | |||||

| KF-3322 | CoCrWCNiSi | Iyafana ne344 | 4060 | CO106 1256 | 6 46 | |

| KF-3323 | CoCrWCNiSi | |||||

| KF-3324 | CoCrWCNiSi | 344 | 45 x40 | CO105 / CO285 | 90 | |

| KF-3325 | CoCrWCNiSi |

Inkcazo

| Uphawu | Igama lemveliso | Ikhemistri (wt%) | Ukuqina | Ubushushu | Iipropati & neSicelo | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cr | W | C | Ni | Si | B | Mo | Co | |||||

| KF-331 | CoCrMoSi | 8 | 2.6 | 28 | UBhal. | HRC 54 | ≤ 840ºC | •Ukumelana nokunxiba, ukuxhathisa ukukrwempa •Ukumelana nokubola | ||||

| KF-333 | CoCrMoSi | 17.5 | 3.4 | 35 | UBhal. | HRC53 | ≤ 840ºC | •Ukumelana nokunxiba, ukuxhathisa ukukrwempa •Ukumelana nokubola | ||||

| KF-332 | CoCrWCNiSi | 25 | 7.5 | 0.8 | 10 | 1 | UBhal. | HRC 30 | ≤ 840ºC | •Isihlalo seValve •Ukuthwala •Blade •Efana neSt1 | ||

| KF-3321 | CoCrWCNiSi | 30 | 4 | 1.5 | 3 | 1.4 | 4 | UBhal. | HRC45 | ≤ 840ºC | •I-PTA, i-APS, i-HVOF, i-laser cladding, i-spherical •Iivalvu zoxinzelelo lobushushu obuphezulu, amazinyo asarha, izikrufu ezikhuphayo •Efana neSt12 | |

| KF-3322 | CoCrWCNiSi | 30 | 4.5 | 1 | 3 | 1.4 | UBhal. | HRC 40 | ≤ 840ºC | •I-PTA, i-APS, i-HVOF, i-laser cladding, i-spherical •Iivalvu ze-injini, amaxabiso oxinzelelo oluphezulu lobushushu, iiblade ze-injini ye-turbo •Efana neSt6 •Ukumelana nokunxiba kakuhle kubushushu obuphezulu | ||

| KF-3323 | CoCrWCNiSi | 28 | 0.25 | 3 | 1 | 5.5 | UBhal. | HRC55 | ≤ 840ºC | •Iincakuba zomoya •Iivalvu zolwelo •Isihlalo seValve | ||

| KF-3324 | CoCrWCNiSi | 25.5 | 7.5 | 0.5 | 10.5 | 1 | UBhal. | HRC 30 | ≤ 840ºC | •Imibundo yokukhupha •Iintsimbi zeinjini yegesi | ||

| KF-3325 | CoCrWCNiSi | 21.0 | 5 | 0.1 | 1 | 1.6 | 2.4 | UBhal. | HRC50 | ≤ 840ºC | •I-PTA, i-APS, i-HVOF, i-laser cladding, i-spherical • Ukumelana nobushushu obuphezulu •Iivalvu zesithuthuthu •Ukuzikhupha | |