I-Copper Base Alloy ene-conductivity egqwesileyo yombane kunye ne-thermal

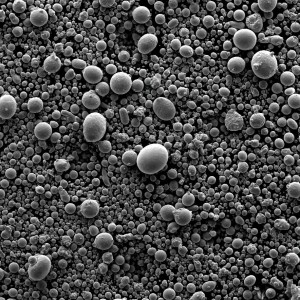

Inkcazo

Umbane ogqwesileyo kunye ne-thermal conductivity, i-non-magnetic kwaye isebenziseka kwi-EMI yokukhusela, ikwazi ukumelana nee-inks ezinobungozi, isetyenziselwa ukulungisa iindawo ze-alloy base-copper.

I-CuAl-90/10 i-alloy yobhedu kunye ne-90% yobhedu kunye ne-10% ye-aluminium, eyenza ibe yinto eguquguqukayo yoluhlu lwezicelo.

Iinketho zohlobo ziquka KF-320, KF-325, KF-321, kunye nokunye.

Enye yezinto eziphambili zokusetyenziswa kweCuAl-90/10 kukulungiswa nokugcinwa kwezinto zobhedu kunye nobhedu lwe-alloy.Iipropati zayo zenza ukuba kube yinto ekhethekileyo yokukhetha kwiindawo ezithambileyo zokuxhasa iibheringi.Ukongeza, iCuAl-90/10 ihlala isetyenziswa kumacandelo eenqwelomoya kunye neecompressor zomoya ngenxa yombane wayo ophezulu kunye nobushushu obuphezulu.Ayinamagnetic kwaye iluncedo ekukhuseleni i-EMI, iyenza ibe lolona khetho lufanelekileyo kwizixhobo zombane.

Enye inzuzo ye-CuAl-90/10 kukuchasana kwayo nee-inki ezidliwayo, okwenza kube yinto efanelekileyo yokusetyenziswa kwishishini lokushicilela.Ingasetyenziselwa ukulungisa iinxalenye ze-alloy base basecopper, igxininisa ngakumbi ubuninzi bayo.

Ngokubhekiselele kwiimpawu zayo zemishini, i-CuAl-90/10 inikezela ukuxhathisa okulungileyo kunye namandla aphezulu, okwenza kube yinto ehlala ixesha elide kunye nexesha elide.Kwakhona kulula ukwenza umatshini kunye ne-weld, evumela ukwenziwa lula kunye nomsebenzi wokulungisa.

Ngokubanzi, iCuAl-90/10 lolona khetho lubalaseleyo kuluhlu lwezicelo ngenxa yokudityaniswa kwayo koomatshini, umbane, kunye neempawu ezishushu.Ukuguquguquka kwayo kuyenza ibe yimathiriyeli exabisekileyo kumashishini ahlukeneyo, kubandakanya ukuhamba ngenqwelomoya, umbane, kunye noshicilelo.

Iimveliso ezifanayo

| Uphawu | Igama lemveliso | I-AMPERIT | I-METCO/AMDRY | WOKA | PRAXAIR | PAC |

| KF-320 | CuAl-90/10 | 511004 | CU114CU104 | 16 | ||

| KF-325 | CuAl-90/10 | 511004 | CU114CU104 | 16 | ||

| KF-321 | CuNiIn | 58 | CU101CU102 | 658 |

Inkcazo

| Uphawu | Igama lemveliso | Ikhemistri (wt%) | Ukuqina | Ubushushu | Iipropati & neSicelo | ||||

|---|---|---|---|---|---|---|---|---|---|

| Al | Ni | In | Fe | Cu | |||||

| KF-320 | CuAl-90/10 | 10 | ≤1.0 | UBhal. | HRC <20 | ≤ 400ºC | • Ubungakanani bokulungiswa kwezinto zobhedu kunye nobhedu lwe-alloy, indawo yokuxhasa ethambileyo yeebheringi | ||

| KF-325 | CuAl-90/10 | 10 | 0.7-1.5 | UBhal. | HRC <20 | ≤ 400ºC | • Ubungakanani bokulungiswa kwezinto zobhedu kunye nobhedu lwe-alloy, indawo yokuxhasa ethambileyo yeebheringi | ||

| KF-321 | CuNiIn | 36 | 5 | UBhal. | HRC <20 | ≤ 400ºC | •Amacandelo omoya, isicinezeli somoya | ||