Umzi-mveliso we-NiAl yokugquma umgubo

IKomishini yethu kukubonelela abasebenzisi bethu bokugqibela kunye nabathengi ngowona mgangatho uphezulu kunye nokhuphiswano lwezentengiso zedijithali kwiFactory ye-NiAl cladding powder, iLebhu yethu ngoku "yiLebhu yeSizwe ye-turbo ye-injini ye-diesel", kwaye singabanini beqela elinamava le-R&D kunye novavanyo olupheleleyo. indawo.

Ikhomishini yethu kukubonelela abasebenzisi bethu bokugqibela kunye nabathengi ngowona mgangatho uphezulu kunye nokhuphiswano lwentengiso yedijithaliChina NiAl cladding powder, Injongo yethu elandelayo kukugqithisa okulindelweyo kuye wonke umxhasi ngokunikezela ngenkonzo ebalaseleyo yabathengi, ukwanda kokuguquguquka kunye nexabiso elikhulu.Lilonke, ngaphandle kwabathengi bethu asikho;ngaphandle kwabathengi abonwabileyo nabanelisekile ngokupheleleyo, siyasilela.Kudala sikhangela ihoseyile, Drop ship.Kuya kufuneka uqhagamshelane nathi ukuba unomdla kwintengiso yethu.Ndiyathemba ukwenza ishishini nani nonke.Umgangatho ophezulu kunye nokuthunyelwa ngokukhawuleza!

Inkcazo

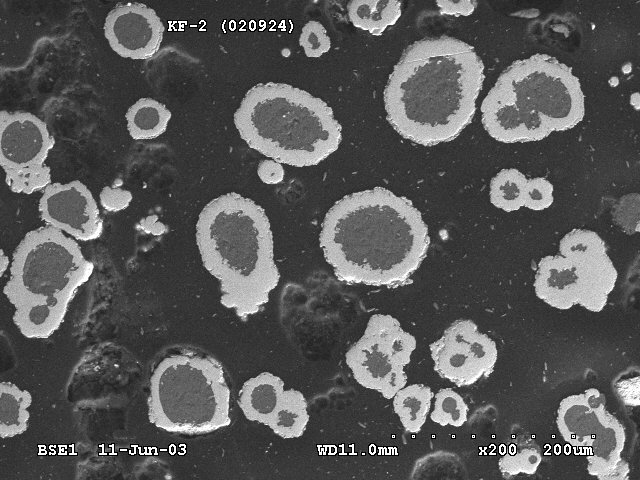

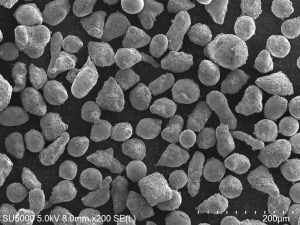

Siyazingca ukwazisa iimveliso ezimbini ezisekelwe kwi-NiAl powder: KF-2 kunye ne-KF-6.Ezi mveliso zimbini zisebenzisa izilinganiso ezahlukeneyo ze-NiAl powder kwaye zineempawu ezizodwa kunye nokusetyenziswa.

I-KF-2 isebenzisa i-NiAl82/18, equlethe i-82% ye-Ni kunye ne-18% ye-Al.Le mveliso ifanelekile kwizicelo ezinobushushu obuphezulu bokusebenza obungama-650°C.Inika i-dense, machinable, i-oxidation-resistant, kunye ne-resistant-resistant coating kunye neempawu zokuzibophelela.Kuhlala kukho ukusabela kwe-exothermic ngexesha lenkqubo yokutshiza, okukhokelela kumandla okudibanisa okugqwesileyo okungaphezulu kwemathiriyeli ye-Ni5Al.I-KF-2 ilungele ukulungiswa kunye nokuvelisa kwakhona i-carbon steel machinable kunye ne-corrosion-resistant steel, kwaye ingasetyenziselwa ukudibanisa iileyile zeekeramics kunye nezinto ezinokunxiba.

I-KF-6 isebenzisa i-NiAl95/5, equlethe i-95% ye-Ni kunye ne-5% ye-Al.Le mveliso ifanelekile kwizicelo ezinobushushu obuphezulu bokusebenza obuyi-800°C kwaye ingasetyenziswa kusetyenziswa iindlela ezahlukeneyo zokutshiza ezifana nedangatye, i-APS, kunye ne-HVOF.Ikwabonelela nge-dense, machinable, i-oxidation-resistant, kunye ne-resistant-resistant coating eneempawu zokuzibophelela.Kuhlala kukho ukusabela okugqithisileyo ngexesha lenkqubo yokutshiza, okukhokelela kumandla abalaseleyo okudibanisa.I-KF-6 ingasetyenziselwa ukulungisa kunye nokuvelisa kwakhona i-carbon steel machinable kunye ne-corrosion-resistant steel, kunye neengqimba ezibophelelayo zeeseramics kunye nezinto ezinokunxiba.

Isishwankathelo, zombini i-KF-2 kunye ne-KF-6 ziimveliso ezisekwe ngumgubo we-NiAl ezinika amandla okubopha okugqwesileyo kunye nokumelana nokunxiba.I-KF-2, equlethe ipesenti ephantsi ye-NiAl powder (NiAl82 / 18), ifanelekile kwizicelo ezinobushushu obuphezulu be-650 ° C, ngelixa i-KF-6, kunye nepesenti ephezulu ye-NiAl powder (NiAl95 / 5), inokumelana namaqondo aphezulu ukuya kuma 800°C kwaye ingagalelwa kusetyenziswa iindlela ezahlukeneyo zokutshiza.Zombini iimveliso zilungele ukulungiswa kunye nokuvelisa kwakhona i-carbon steel machinable kunye ne-corrosion-resistant steel, kunye ne-bonding layers ye-ceramics kunye nezinto ezinokunxiba.Ukukhetha phakathi kwe-KF-2 kunye ne-KF-6 kuxhomekeke kwiimfuno ezithile zesicelo kunye nobushushu obuphezulu bokusebenza obufunekayo.

Iimveliso ezifanayo

| Uphawu | Igama lemveliso | I-AMPERIT | I-METCO/AMDRY | WOKA | PRAXAIR | PAC |

| KF-2 | NiAl82/18 | 404NS | ||||

| KF-6 | NiAl95/5 | 282 | 956450NS | NI-109 | 906 |

Inkcazo

| Uphawu | Igama lemveliso | Ikhemistri (wt%) | Ukuqina | Ubushushu | Iipropati & neSicelo | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Al | W | Mo | Cr | Al2O3 | MoS2 | WC | C | Fe | Ni | |||||

| KF-2 | NiAl82/18 | 20 | UBhal. | HRC 20 | ≤ 800ºC | •Idangatye, APS, Max.iqondo lobushushu lokusebenza 650°C. •Ishinyene kwaye iyakwazi ukumelana ne-oxidation kwaye inxibe i-coating ekwaziyo ukumelana. | ||||||||

| KF-6 | NiAl95/5 | 5 | UBhal. | HRC 20 | ≤ 800ºC | •Flame, APS, HVOF, Max.iqondo lobushushu lokusebenza 800°C •Ishinyene kwaye iyakwazi ukumelana ne-oxidation kwaye inxibe i-coating ekwaziyo ukumelana | ||||||||

| KF-20 | Ni-MoS₂ | 22 | UBhal. | HRC 20 | ≤ 500ºC | •Isetyenziselwa iindawo zokutywina ezishukumayo kunye namakhonkco okutywina agubayo •Ingasetyenziswa njengesixhobo sokukhuhlana okuphantsi | ||||||||

| KF-21T | Ni-Graphite 75/25 | 25 | UBhal. | HRC 20 | ≤ 480ºC | •Idangatye, uMax.ubushushu bokusebenza 480 ° C 1. Ukunxiba imathiriyeli ye-turbo compressor •Isebenza kwi-nickel alloy kunye nentsimbi • Iimveliso ezinomxholo ophezulu wegraphite zifanelekile kwiindawo ze-titanium ngaphandle komphetho •Umxholo wegraphite ophezulu uya kuphucula ukusebenza kokuthambisa •Umxholo we-nickel ophezulu uya kuphucula ukuxhathisa ukhukuliseko • Iimveliso ezifanayo zahlukile ngenxa yeempawu ezahlukeneyo ze-OEM | ||||||||

| KF-22T/R | Ni-Graphite 60/40 | 50 | UBhal. | HRC 20 | ≤ 480ºC | |||||||||

| KF-21R | Ni-Graphite 75/25 | 25 | UBhal. | HRC 20 | ≤ 480ºC | |||||||||

| KF-45 | Ni-Al2O3 77/23 | 23 | UBhal. | HRC 40 | ≤ 800ºC | •Idangatye,APS, ngokungaqhelekanga •Ingasetyenziselwa ukunyibilikisa i-crucible, i-terminal seal surface kunye nomphezulu wokungunda njengomaleko okhuselayo | ||||||||

| KF-56 | I-Ni-WC 16/84 | UBhal. | 12 | HRC 62 | ≤ 400ºC | •Idangatye,APS, ngokungaqhelekanga •Ukumelana nokubethelwa ngehamile, ukhukuliseko, ukukrazuka kunye nokugruzuka ukutyibilika | ||||||||

| KF-50 | Ni-WC10/90 | UBhal. | 10 | HRC 62 | ≤ 400ºC | •Idangatye, ngokungaqhelekanga •Ukumelana nokubethelwa ngehamile, ukhukuliseko, ukukrazuka kunye nokugruzuka ukutyibilika | ||||||||

| KF-91Fe | Fe-WC | 4 | 27 | 9.5 | UBhal. | 5.5 | HRC 40 | ≤ 550ºC | •Flame, APS, irregular, Max.iqondo lobushushu lokusebenza 815°C. •Nxiba imathiriyeli yokugquma ekwaziyo ukusetyenziselwa ukulungisa i-tank brake pad | |||||

| KF-110 | I-NiCr-Al 95/5 | 5 | 7.5 | UBhal. | HRC 20 | ≤ 800ºC | •Idangatye, APS, Max.iqondo lobushushu lokusebenza 980°C. •Ukutshiza ngePlasma ngokuzidibanisa | |||||||

| KF-113A | I-NiCrAl-CoY2O3 | Cr+Al:20, Ni+Co:75 | HRC 20 | ≤ 900ºC | •APS,HVOF, irregular, Max.iqondo lobushushu lokusebenza 980°C. •Isebenza ekulungiseni umaleko webhondi yobushushu obuphezulu okanye ukunxiba / ukusetyenzwa ngokungafanelekanga kwamalungu | |||||||||

| KF-133 | NiMoAl | 5 | 5 | UBhal. | HRC 20 | ≤ 650ºC | • Ukuzibophelela ngokwakho, ukugquma okuqinileyo okuqhelekileyo ukuze kufakwe isicelo •Inzima, enokumelana ne-corrosion elungileyo kunye nokusebenza kwempembelelo •Isetyenziselwa iindawo zoomatshini, isitulo sokuthwala kunye nevalve | |||||||

| KF-31 | Ni-Diatomite 75/25 | •Flame,APS, irregular, Max.iqondo lobushushu lokusebenza 650°C. •Ukwenzela ukugqunywa kwetywina okugubayo, kubandakanywa iindawo zokutywina ezihambayo, imisesane yokutywina enokugutyungelwa, imathiriyeli enokukhuhlana okuphantsi. | ||||||||||||

IKomishini yethu kukubonelela abasebenzisi bethu bokugqibela kunye nabathengi ngowona mgangatho uphezulu kunye nokhuphiswano lwezentengiso zedijithali kwiFactory ye-NiAl cladding powder, iLebhu yethu ngoku "yiLebhu yeSizwe ye-turbo ye-injini ye-diesel", kwaye singabanini beqela elinamava le-R&D kunye novavanyo olupheleleyo. indawo.

Factory ForChina NiAl cladding powder, Injongo yethu elandelayo kukugqithisa okulindelweyo kuye wonke umxhasi ngokunikezela ngenkonzo ebalaseleyo yabathengi, ukwanda kokuguquguquka kunye nexabiso elikhulu.Lilonke, ngaphandle kwabathengi bethu asikho;ngaphandle kwabathengi abonwabileyo nabanelisekile ngokupheleleyo, siyasilela.Kudala sikhangela ihoseyile, Drop ship.Kuya kufuneka uqhagamshelane nathi ukuba unomdla kwintengiso yethu.Ndiyathemba ukwenza ishishini nani nonke.Umgangatho ophezulu kunye nokuthunyelwa ngokukhawuleza!