I-MCrAlY Alloy enokumelana nobushushu obuphezulu

Inkcazo

Uphawu:KF-301 KF-308 KF-309 KF-336 KF-337 KF-339… Uhlobo: Igesi yeatom

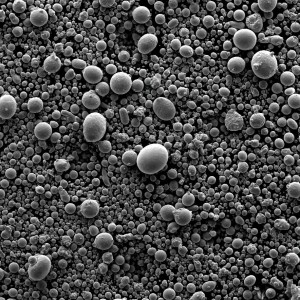

Iinkcazelo Ngeempawu Zomgubo:Ukuqulunqwa kweMichiza: MCrAlY (M = Fe, Ni, okanye Co) Ubungakanani beNqanaba: -45 +15 µm Ubunyulu: ≥ 99.5%

Isicelo:Iipowders ze-MCrAlY Alloy zisetyenziswa ngokubanzi kwizicelo zobushushu obuphezulu ngenxa yeempawu zazo ezizodwa.Ngokuqhelekileyo zisetyenziswa njengeedyasi zebhondi kwimiqulu ye-metallurgical, i-hot dip sink rolls, kunye nemiqulu yokushisa yokushisa.Ukongeza, zisetyenziswa kumzi mveliso we-aerospace ukwenza izinto ze-injini yegesi, izikhuselo zobushushu, kunye neenjini ze-aero.

Iimpawu ze-MCrAlY Alloy

I-1.Ukumelana nobushushu obuphezulu: I-MCrAlY Alloy powders ibonisa ukuchasana okugqwesileyo kumaqondo aphezulu.Le propathi ibenza balungele ukusetyenziswa kwizicelo zobushushu obuphezulu obunje ngee turbines zerhasi, iziko lokunyanga ubushushu, kunye neeroli ze-metallurgical.

Iipropathi ze-2.Antioxidant: I-MCrAlY Alloy powders ixhathisa kakhulu kwi-oxidation kumaqondo aphezulu okushisa, okwenza kube yinto efanelekileyo yokusetyenziswa kwiindawo ezinzima apho i-oxidation ingenzeka khona, njengakwii-injini zegesi kunye nezikhuselo zokushisa.

I-3.I-Hot Corrosion Resistance: I-MCrAlY Alloy powders ibonisa ukuchasana okugqwesileyo kwi-corrosion eshushu, ibenza ibe yinto efanelekileyo yokusetyenziswa kwizicelo apho izinto ezibonakalayo zibonakaliswe kwiindawo ezinobungozi kumaqondo aphezulu okushisa.

I-4.Thermal Barrier Substrate: I-MCrAlY Alloy powders isoloko isetyenziswa njenge-thermal barrier substrates ngenxa ye-conductivity egqwesileyo ye-thermal kunye neempawu zokwandisa i-thermal.Zisetyenziselwa kunye neengubo ze-ceramic ukukhusela izinto eziphantsi kwiindawo eziphezulu zokushisa.

Lilonke, i-MCrAlY Alloy powders zizixhobo eziguquguqukayo ezibonisa iipropathi ezibalaseleyo zobushushu obuphezulu, zizenza zilungele ukusetyenziswa kwiinkqubo ezahlukeneyo kumashishini ahlukeneyo.Iimpawu zabo ezikhethekileyo, ezibandakanya ukumelana nobushushu obuphezulu, iipropathi ze-antioxidant, ukuxhathisa kwe-corrosion eshushu, kunye neempawu ze-thermal barrier substrate, zibenza babe lukhetho oludumileyo kwizicelo eziphezulu zokushisa.

Iimveliso ezifanayo

| Uphawu | Igama lemveliso | I-AMPERIT | I-METCO/AMDRY | WOKA | PRAXAIR | PAC |

| KF-301 | ||||||

| KF-308 | NiCrAlY | 9621 | ||||

| KF-309 | NiCoCrAlY | |||||

| KF-336 | CoCrAlSiY | |||||

| KF-337 | CoNiCrAlY | 9954 | ||||

| KF-339 | I-CoCrAlYTaSiC |

Inkcazo

| Uphawu | Igama lemveliso | Ikhemistri (wt%) | Ukuqina | Ubushushu | Iipropati & neSicelo | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cr | Al | Y | Ta | Si | C | Co | Ni | |||||

| KF-301 | •APS, HVOF, detonation-gun, spherical • Iidyasi zebhondi yobushushu obuphezulu | |||||||||||

| KF-308 | Nickel Chromium Aluminium Yttrium Alloy | 25 | 11 | 1 | UBhal. | HRC 20-30 | ≤ 950ºC | •I-Metallurgical roll, i-dip sink roll eshushu, i-furnace roll yonyango lobushushu. • Iincakuba ze-injini yomoya, i-injini yegesi, isikhuselo sobushushu | ||||

| KF-309 | Nickel Cobalt Chromium Aluminiyam Yttrium Ingxubevange | 25 | 6 | 0.5 | 22 | UBhal. | HRC 20-30 | ≤ 950ºC | • Ukumelana nobushushu obuphezulu, i-antioxidant. •Ukumelana nomhlwa okushushu. •I-Thermal barrier substrate | |||

| KF-336 | Cobalt Chromium Aluminiyam Silicon Yttrium Ingxubevange | 29 | 7 | 0.5 | 3 | UBhal. | HRC 20-30 | ≤ 1000ºC | • Ukumelana nobushushu obuphezulu, i-antioxidant. • Ukumelana nokutshisa kwe-corrosion, i-substrate | |||

| KF-337 | ICobalt Chromium Aluminium Yttrium Alloy | 23 | 6 | 0.4 | UBhal. | 30 | HRC 20-30 | ≤ 1050ºC | • Ukumelana nobushushu obuphezulu, i-antioxidant. • Ukumelana nokutshisa okutshisayo, i-thermal barrier substrate | |||

| KF-339 | ICobalt Chromium Aluminium Yttrium Alloy | 24 | 7.5 | 0.8 | 10 | 0.8 | 2 | UBhal. | ≤ 1100ºC | •APS, HVOF, detonation-gun, spherical •I-Metallurgical roll, i-furnace roll yobushushu obuphezulu. •Iintsimbi zerotha ye-injini yomoya, iincakuba zesikhokelo kunye namaphiko einjini yegesi | ||