I-Ni-Graphite Cladding powder ene-conductivity yombane

Inkcazo

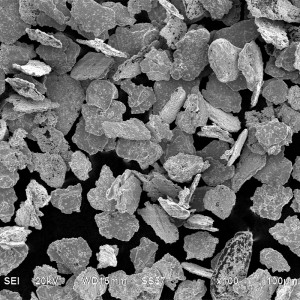

I-Ni-Graphite Cladding powder yimathiriyeli ekhethekileyo eyenzelwe ukubonelela ukusebenza okuphezulu kwizicelo ezifunwayo zemizi-mveliso.Lo mgubo wemveliso ufakwe ngokwekhemikhali kunye noxinzelelo oluphezulu lwenickel kunye negraphite, oko kuyenza ibe lolona khetho lufanelekileyo lokusetyenziswa ekunxibeni izinto ze-turbo compressors, i-nickel alloy, kunye namalungu entsimbi.

Enye yezinto eziphambili ze-Ni-Graphite Cladding powder ngumxholo wayo ophezulu wegraphite.Olu phawu luphucula ukusebenza kokuthanjiswa komgubo, okwenza kube lukhetho oludumileyo lokusetyenziswa kwiindawo zetitanium ezingenawo umphetho.Ukongezelela, umxholo ophezulu we-nickel wepowder uphucula ukuxhathisa ukukhukuliseka kwayo, uqinisekisa ukuba ubonelela ngokusebenza ngokufanelekileyo kwiindawo ezinzima zoshishino.

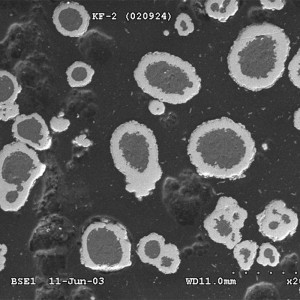

I-Ni-Graphite Cladding powder ifumaneka ngeendlela ezimbini ezahlukeneyo: i-KF-21 i-Ni-Graphite 75/25 kunye ne-KF-22 ye-Ni-Graphite 60/40.Ezi zimbini zemiqulu zinemilinganiselo eyahlukeneyo ye-nickel kunye ne-graphite, ezenza zilungele iintlobo ezahlukeneyo zezicelo zoshishino.Umzekelo, i-KF-21 ye-Ni-Graphite 75/25 inomxholo ophezulu we-nickel, oyenza ilungele ukusetyenziswa kwizicelo ezifuna ukuxhathisa okungaphezulu kokukhukuliseka.

Ukongeza kwiimpawu zayo zokusebenza eziphezulu, i-Ni-Graphite Cladding powder nayo ininzi kakhulu.Ingasetyenziswa kuluhlu olubanzi lwezicelo zamashishini, kubandakanya i-turbo compressors, i-nickel alloy, kunye nentsimbi.Ngaphezu koko, ukumelana nomlilo kunye nobushushu obuphezulu bokusebenza kwe-480 ° C kwenza kube lukhetho oluthembekileyo lokusetyenziswa kwizicelo zobushushu obuphezulu.

Xa kuziwa ekukhetheni i-Ni-Graphite Cladding powder efanelekileyo kwisicelo sakho soshishino, kubalulekile ukuqwalasela iinkcukacha ezithile ze-OEM zezixhobo zakho.I-KF-21 ifana ne-AMPERIT 205, i-METCO/AMDRY 307NS, i-PRAXAIR NI-114, kunye ne-PAC 138, ngelixa i-KF-22 ifana ne-AMPERIT 200 kunye ne-Durabrade 2211.

Ukuqukumbela, i-Ni-Graphite Cladding powder yinto ekhethekileyo kakhulu ebonelela ngokusebenza okuphezulu kwizicelo ezifunwayo zoshishino.Umxholo wayo ophezulu wegraphite kunye nomxholo ophezulu we-nickel uwenza ukuba ube lolona khetho lufanelekileyo lokusebenzisa izinto zokunxiba ze-turbo compressors, i-nickel alloy, kunye nentsimbi.Ngokuguquguquka kwayo, ukumelana nomlilo, kunye nobushushu obuphezulu bokusebenza, i-Ni-Graphite Cladding powder lukhetho oluthembekileyo kuluhlu olubanzi lwezicelo zoshishino.

Iimveliso ezifanayo

| Uphawu | Igama lemveliso | I-AMPERIT | I-METCO/AMDRY | WOKA | PRAXAIR | PAC |

| KF-21T/R | Ni-Graphite 75/25 | 205 | 307NS | NI-114 | 138 | |

| KF-22T/R | Ni-Graphite 60/40 | 200 | Durabrade 2211 |

Inkcazo

| Uphawu | Igama lemveliso | Ikhemistri (wt%) | Ukuqina | Ubushushu | Iipropati & neSicelo | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Al | W | Mo | Cr | Al2O3 | MoS2 | WC | C | Fe | Ni | |||||

| KF-2 | NiAl82/18 | 20 | UBhal. | HRC 20 | ≤ 800ºC | •Idangatye, APS, Max.iqondo lobushushu lokusebenza 650°C. •Ishinyene kwaye iyakwazi ukumelana ne-oxidation kwaye inxibe i-coating ekwaziyo ukumelana. | ||||||||

| KF-6 | NiAl95/5 | 5 | UBhal. | HRC 20 | ≤ 800ºC | •Flame, APS, HVOF, Max.iqondo lobushushu lokusebenza 800°C •Ishinyene kwaye iyakwazi ukumelana ne-oxidation kwaye inxibe i-coating ekwaziyo ukumelana | ||||||||

| KF-20 | Ni-MoS₂ | 22 | UBhal. | HRC 20 | ≤ 500ºC | •Isetyenziselwa iindawo zokutywina ezishukumayo kunye namakhonkco okutywina agubayo •Ingasetyenziswa njengesixhobo sokukhuhlana okuphantsi | ||||||||

| KF-21T | Ni-Graphite 75/25 | 25 | UBhal. | HRC 20 | ≤ 480ºC | •Idangatye, uMax.ubushushu bokusebenza 480 ° C 1. Ukunxiba imathiriyeli ye-turbo compressor •Isebenza kwi-nickel alloy kunye nentsimbi • Iimveliso ezinomxholo ophezulu wegraphite zifanelekile kwiindawo ze-titanium ngaphandle komphetho •Umxholo wegraphite ophezulu uya kuphucula ukusebenza kokuthambisa •Umxholo we-nickel ophezulu uya kuphucula ukuxhathisa ukhukuliseko • Iimveliso ezifanayo zahlukile ngenxa yeempawu ezahlukeneyo ze-OEM | ||||||||

| KF-22T/R | Ni-Graphite 60/40 | 50 | UBhal. | HRC 20 | ≤ 480ºC | |||||||||

| KF-21R | Ni-Graphite 75/25 | 25 | UBhal. | HRC 20 | ≤ 480ºC | |||||||||

| KF-45 | Ni-Al2O3 77/23 | 23 | UBhal. | HRC 40 | ≤ 800ºC | •Idangatye,APS, ngokungaqhelekanga •Ingasetyenziselwa ukunyibilikisa i-crucible, i-terminal seal surface kunye nomphezulu wokungunda njengomaleko okhuselayo | ||||||||

| KF-56 | I-Ni-WC 16/84 | UBhal. | 12 | HRC 62 | ≤ 400ºC | •Idangatye,APS, ngokungaqhelekanga •Ukumelana nokubethelwa ngehamile, ukhukuliseko, ukukrazuka kunye nokugruzuka ukutyibilika | ||||||||

| KF-50 | Ni-WC10/90 | UBhal. | 10 | HRC 62 | ≤ 400ºC | •Idangatye, ngokungaqhelekanga •Ukumelana nokubethelwa ngehamile, ukhukuliseko, ukukrazuka kunye nokugruzuka ukutyibilika | ||||||||

| KF-91Fe | Fe-WC | 4 | 27 | 9.5 | UBhal. | 5.5 | HRC 40 | ≤ 550ºC | •Flame, APS, irregular, Max.iqondo lobushushu lokusebenza 815°C. •Nxiba imathiriyeli yokugquma ekwaziyo ukusetyenziselwa ukulungisa i-tank brake pad | |||||

| KF-110 | I-NiCr-Al 95/5 | 5 | 7.5 | UBhal. | HRC 20 | ≤ 800ºC | •Idangatye, APS, Max.iqondo lobushushu lokusebenza 980°C. •Ukutshiza ngePlasma ngokuzidibanisa | |||||||

| KF-113A | I-NiCrAl-CoY2O3 | Cr+Al:20, Ni+Co:75 | HRC 20 | ≤ 900ºC | •APS,HVOF, irregular, Max.iqondo lobushushu lokusebenza 980°C. •Isebenza ekulungiseni umaleko webhondi yobushushu obuphezulu okanye ukunxiba / ukusetyenzwa ngokungafanelekanga kwamalungu | |||||||||

| KF-133 | NiMoAl | 5 | 5 | UBhal. | HRC 20 | ≤ 650ºC | • Ukuzibophelela ngokwakho, ukugquma okuqinileyo okuqhelekileyo ukuze kufakwe isicelo •Inzima, enokumelana ne-corrosion elungileyo kunye nokusebenza kwempembelelo •Isetyenziselwa iindawo zoomatshini, isitulo sokuthwala kunye nevalve | |||||||

| KF-31 | Ni-Diatomite 75/25 | •Flame,APS, irregular, Max.iqondo lobushushu lokusebenza 650°C. •Ukwenzela ukugqunywa kwetywina okugubayo, kubandakanywa iindawo zokutywina ezihambayo, imisesane yokutywina enokugutyungelwa, imathiriyeli enokukhuhlana okuphantsi. | ||||||||||||