I-NiAl yokugquma umgubo oqinileyo wokuqina

Inkcazo

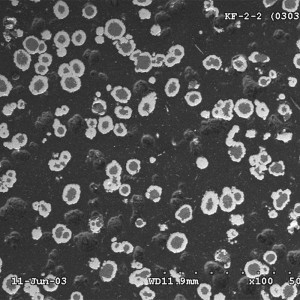

Siyazingca ukwazisa iimveliso ezimbini ezisekelwe kwi-NiAl powder: KF-2 kunye ne-KF-6.Ezi mveliso zimbini zisebenzisa izilinganiso ezahlukeneyo ze-NiAl powder kwaye zineempawu ezizodwa kunye nokusetyenziswa.

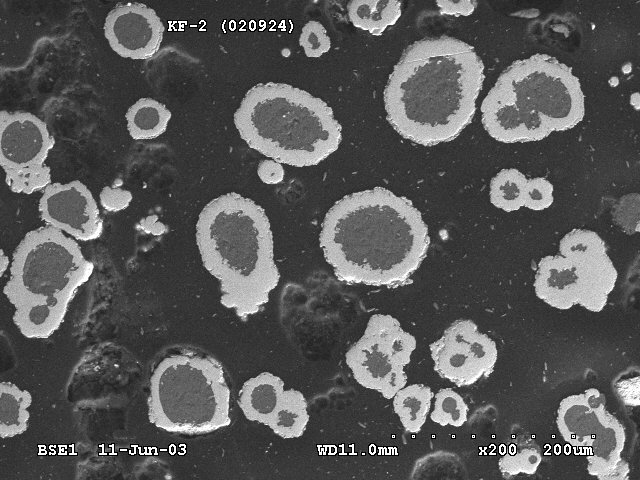

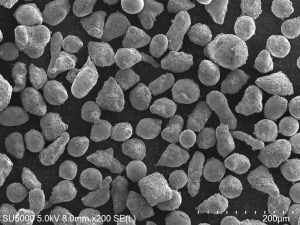

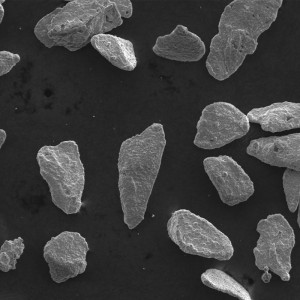

I-KF-2 isebenzisa i-NiAl82/18, equlethe i-82% ye-Ni kunye ne-18% ye-Al.Le mveliso ifanelekile kwizicelo ezinobushushu obuphezulu bokusebenza obungama-650°C.Inika i-dense, machinable, i-oxidation-resistant, kunye ne-resistant-resistant coating kunye neempawu zokuzibophelela.Kuhlala kukho ukusabela kwe-exothermic ngexesha lenkqubo yokutshiza, okukhokelela kumandla okudibanisa okugqwesileyo okungaphezulu kwemathiriyeli ye-Ni5Al.I-KF-2 ilungele ukulungiswa kunye nokuvelisa kwakhona i-carbon steel machinable kunye ne-corrosion-resistant steel, kwaye ingasetyenziselwa ukudibanisa iileyile zeekeramics kunye nezinto ezinokunxiba.

I-KF-6 isebenzisa i-NiAl95/5, equlethe i-95% ye-Ni kunye ne-5% ye-Al.Le mveliso ifanelekile kwizicelo ezinobushushu obuphezulu bokusebenza obuyi-800°C kwaye ingasetyenziswa kusetyenziswa iindlela ezahlukeneyo zokutshiza ezifana nedangatye, i-APS, kunye ne-HVOF.Ikwabonelela nge-dense, machinable, i-oxidation-resistant, kunye ne-resistant-resistant coating eneempawu zokuzibophelela.Kuhlala kukho ukusabela okugqithisileyo ngexesha lenkqubo yokutshiza, okukhokelela kumandla abalaseleyo okudibanisa.I-KF-6 ingasetyenziselwa ukulungisa kunye nokuvelisa kwakhona i-carbon steel machinable kunye ne-corrosion-resistant steel, kunye neengqimba ezibophelelayo zeeseramics kunye nezinto ezinokunxiba.

Isishwankathelo, zombini i-KF-2 kunye ne-KF-6 ziimveliso ezisekwe ngumgubo we-NiAl ezinika amandla okubopha okugqwesileyo kunye nokumelana nokunxiba.I-KF-2, equlethe ipesenti ephantsi ye-NiAl powder (NiAl82 / 18), ifanelekile kwizicelo ezinobushushu obuphezulu be-650 ° C, ngelixa i-KF-6, kunye nepesenti ephezulu ye-NiAl powder (NiAl95 / 5), inokumelana namaqondo aphezulu ukuya kuma 800°C kwaye ingagalelwa kusetyenziswa iindlela ezahlukeneyo zokutshiza.Zombini iimveliso zilungele ukulungiswa kunye nokuvelisa kwakhona i-carbon steel machinable kunye ne-corrosion-resistant steel, kunye ne-bonding layers ye-ceramics kunye nezinto ezinokunxiba.Ukukhetha phakathi kwe-KF-2 kunye ne-KF-6 kuxhomekeke kwiimfuno ezithile zesicelo kunye nobushushu obuphezulu bokusebenza obufunekayo.

Iimveliso ezifanayo

| Uphawu | Igama lemveliso | I-AMPERIT | I-METCO/AMDRY | WOKA | PRAXAIR | PAC |

| KF-2 | NiAl82/18 | 404NS | ||||

| KF-6 | NiAl95/5 | 282 | 956450NS | NI-109 | 906 |

Inkcazo

| Uphawu | Igama lemveliso | Ikhemistri (wt%) | Ukuqina | Ubushushu | Iipropati & neSicelo | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Al | W | Mo | Cr | Al2O3 | MoS2 | WC | C | Fe | Ni | |||||

| KF-2 | NiAl82/18 | 20 | UBhal. | HRC 20 | ≤ 800ºC | •Idangatye, APS, Max.iqondo lobushushu lokusebenza 650°C. •Ishinyene kwaye iyakwazi ukumelana ne-oxidation kwaye inxibe i-coating ekwaziyo ukumelana. | ||||||||

| KF-6 | NiAl95/5 | 5 | UBhal. | HRC 20 | ≤ 800ºC | •Flame, APS, HVOF, Max.iqondo lobushushu lokusebenza 800°C •Ishinyene kwaye iyakwazi ukumelana ne-oxidation kwaye inxibe i-coating ekwaziyo ukumelana | ||||||||

| KF-20 | Ni-MoS₂ | 22 | UBhal. | HRC 20 | ≤ 500ºC | •Isetyenziselwa iindawo zokutywina ezishukumayo kunye namakhonkco okutywina agubayo •Ingasetyenziswa njengesixhobo sokukhuhlana okuphantsi | ||||||||

| KF-21T | Ni-Graphite 75/25 | 25 | UBhal. | HRC 20 | ≤ 480ºC | •Idangatye, uMax.ubushushu bokusebenza 480 ° C 1. Ukunxiba imathiriyeli ye-turbo compressor •Isebenza kwi-nickel alloy kunye nentsimbi • Iimveliso ezinomxholo ophezulu wegraphite zifanelekile kwiindawo ze-titanium ngaphandle komphetho •Umxholo wegraphite ophezulu uya kuphucula ukusebenza kokuthambisa •Umxholo we-nickel ophezulu uya kuphucula ukuxhathisa ukhukuliseko • Iimveliso ezifanayo zahlukile ngenxa yeempawu ezahlukeneyo ze-OEM | ||||||||

| KF-22T/R | Ni-Graphite 60/40 | 50 | UBhal. | HRC 20 | ≤ 480ºC | |||||||||

| KF-21R | Ni-Graphite 75/25 | 25 | UBhal. | HRC 20 | ≤ 480ºC | |||||||||

| KF-45 | Ni-Al2O3 77/23 | 23 | UBhal. | HRC 40 | ≤ 800ºC | •Idangatye,APS, ngokungaqhelekanga •Ingasetyenziselwa ukunyibilikisa i-crucible, i-terminal seal surface kunye nomphezulu wokungunda njengomaleko okhuselayo | ||||||||

| KF-56 | I-Ni-WC 16/84 | UBhal. | 12 | HRC 62 | ≤ 400ºC | •Idangatye,APS, ngokungaqhelekanga •Ukumelana nokubethelwa ngehamile, ukhukuliseko, ukukrazuka kunye nokugruzuka ukutyibilika | ||||||||

| KF-50 | Ni-WC10/90 | UBhal. | 10 | HRC 62 | ≤ 400ºC | •Idangatye, ngokungaqhelekanga •Ukumelana nokubethelwa ngehamile, ukhukuliseko, ukukrazuka kunye nokugruzuka ukutyibilika | ||||||||

| KF-91Fe | Fe-WC | 4 | 27 | 9.5 | UBhal. | 5.5 | HRC 40 | ≤ 550ºC | •Flame, APS, irregular, Max.iqondo lobushushu lokusebenza 815°C. •Nxiba imathiriyeli yokugquma ekwaziyo ukusetyenziselwa ukulungisa i-tank brake pad | |||||

| KF-110 | I-NiCr-Al 95/5 | 5 | 7.5 | UBhal. | HRC 20 | ≤ 800ºC | •Idangatye, APS, Max.iqondo lobushushu lokusebenza 980°C. •Ukutshiza ngePlasma ngokuzidibanisa | |||||||

| KF-113A | I-NiCrAl-CoY2O3 | Cr+Al:20, Ni+Co:75 | HRC 20 | ≤ 900ºC | •APS,HVOF, irregular, Max.iqondo lobushushu lokusebenza 980°C. •Isebenza ekulungiseni umaleko webhondi yobushushu obuphezulu okanye ukunxiba / ukusetyenzwa ngokungafanelekanga kwamalungu | |||||||||

| KF-133 | NiMoAl | 5 | 5 | UBhal. | HRC 20 | ≤ 650ºC | • Ukuzibophelela ngokwakho, ukugquma okuqinileyo okuqhelekileyo ukuze kufakwe isicelo •Inzima, enokumelana ne-corrosion elungileyo kunye nokusebenza kwempembelelo •Isetyenziselwa iindawo zoomatshini, isitulo sokuthwala kunye nevalve | |||||||

| KF-31 | Ni-Diatomite 75/25 | •Flame,APS, irregular, Max.iqondo lobushushu lokusebenza 650°C. •Ukwenzela ukugqunywa kwetywina okugubayo, kubandakanywa iindawo zokutywina ezihambayo, imisesane yokutywina enokugutyungelwa, imathiriyeli enokukhuhlana okuphantsi. | ||||||||||||